Services

Assembly

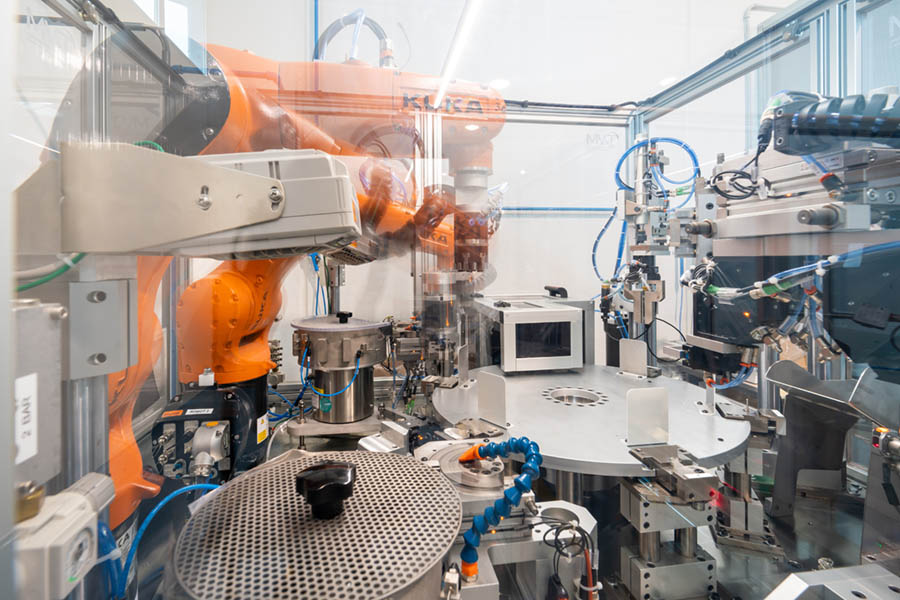

By purchasing parts or receiving them as contract work, we assemble subgroups or finished products, carefully following the operational instructions shared with the customer and providing a full guarantee of the worklists and batches used.

Considering the customisation of the different projects, the equipment needed could be developed by the customer or by Techno Assembly itself, which in this case, takes on the design, development and tests of same.

There are no limits to the number of parts in the worklist for the products we prepare for customers and for the types of test that these need to undergo, whether in terms of appearance or function.

The lean approach, together with the diversity of the projects developed, has allowed us to embark on an island manufacturing process, eliminating, a priori, those bottlenecks that can be created in traditional production lines; this method allows us to achieve an extremely high flexibility when it comes to scheduling, offering the possibility to push and bring forward production orders based on the changed and updated delivery requirements expressed by the end customer.

Product Customisation

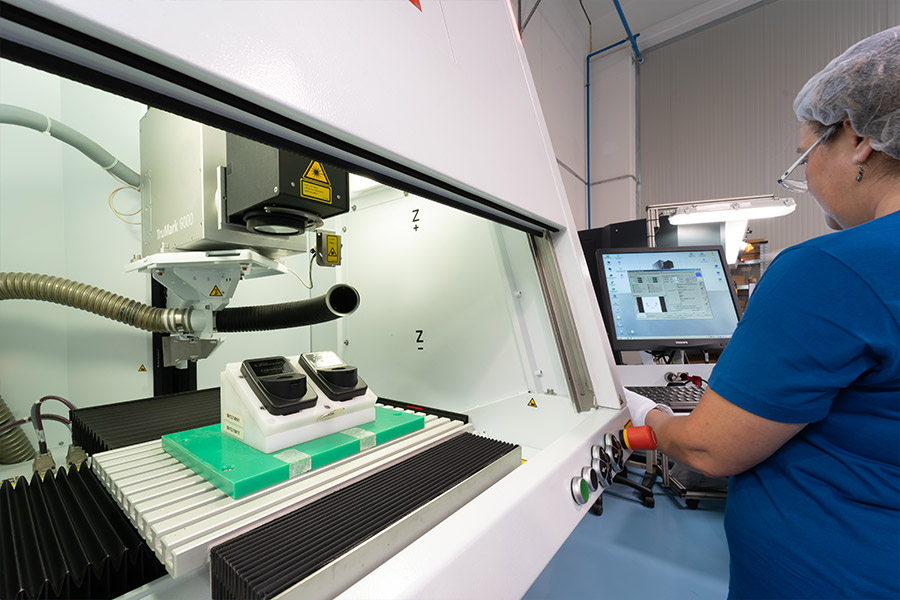

Logos, icons and textures applied to plastic components, glass, metal, wood, cork and leather, represent a valid support to customers offered by Techno Assembly which, thanks to the use of lasers for marking, guarantee quality, durable customisation that resists wear and tear to the products on which they are engraved.

Laser for marking palletised goods to offer the best in competitiveness.

Tests

The test and inspection stages are essential when it comes to guaranteeing the high quality of the service. Assembled subgroups can be validated and then certified by “Gate Test” of a functional/quality type, developed thanks to suppliers who specialise in automation. This equipment is customised according to the different projects and is obviously subjected to the final validation by the customer.

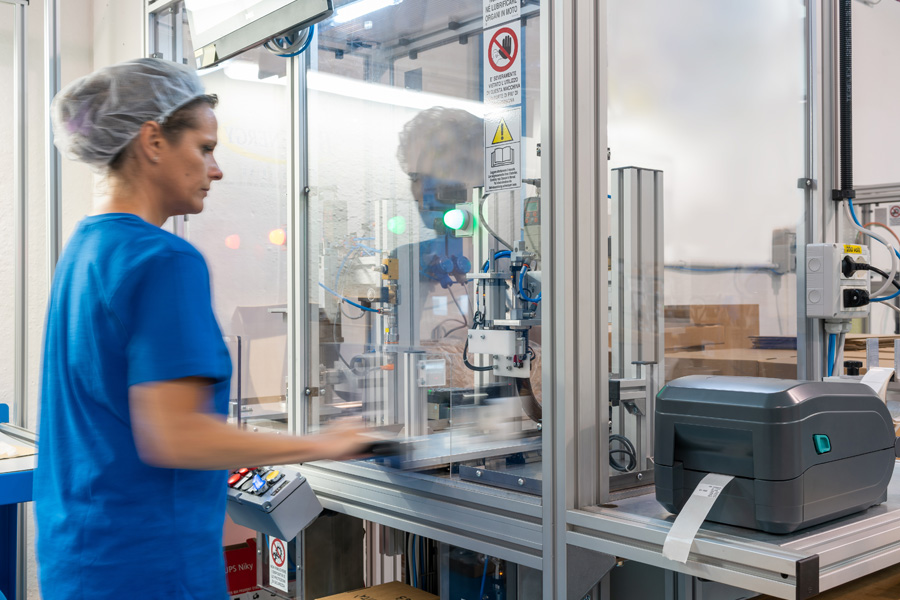

Packing

Even product packing is a service that pushes Techno Assembly towards a careful management of its warehouse worklists. The accessories or finishes of the packaging can, in fact, generate new references/products to manage and deliver to the various customer markets (retail, large supermarket chains, etc).

Contacts

Techno Assembly srl

Via dell’Artigianato 42

32016 Alpago (BL) – Italy

+39 0437 989082

info@technoassembly.it