assembled and pre-assembled products

Laser marking

Techno Assembly: a solid concern

We were founded in 2015, as a sister company of Elettroplast, leading company in moulding technical and aesthetic components in thermoplastic. Experience has allowed us to identify the need to offer a highly specialised surface.

Our vocation is clear: offering effective answers to a market that is continually looking to source subassemblies that are assembled and finished; a market needing monitored, tried and tested, and personalised products that can reach customers’ assembly lines in free pass.

Today, our company is recognised as a solid concern that has had the ability to organise itself according to lean processes, both from organisational and production viewpoints.

Timing and saving are in fact essential aims of what we do. We work daily to monitor production, ensuring the effectiveness of the processes we use, eliminating inefficiencies and guaranteeing costs in line with customer requirements and market demand.

Expert personnel

We are proud of our team. Flexibility, dynamism and the ability to find solutions to a complex range of needs are key elements in our modus operandi.

Our know-how makes it possible to quickly assimilate the processes of the different projects, sharing timely analyses aimed at simplifying and optimizing the different processes.

For the food industry, our 1,200 sq m plant uses “food contact” processes every day to guarantee the safety of the products supplied.

One time in a Lean way

Multinationals have invested time and resources to eliminate any short circuits in the company processes used through the years. Techno Assembly has been fortunate in its ability to design new processes, thanks to its consolidated know-how and to the tried and tested strategies of the parent company.

We have chosen to implement and take ownership of “doing something well the first time”, thereby eliminating the down times that then turn into useless costs for the end customer.

Why choose us?

Lean production

We have the capability to optimise flows, with machining as the means we use to satisfy our customers.

Timing

punctuality is now a “must” and of course, this is guaranteed by correct flow programming.

Processing

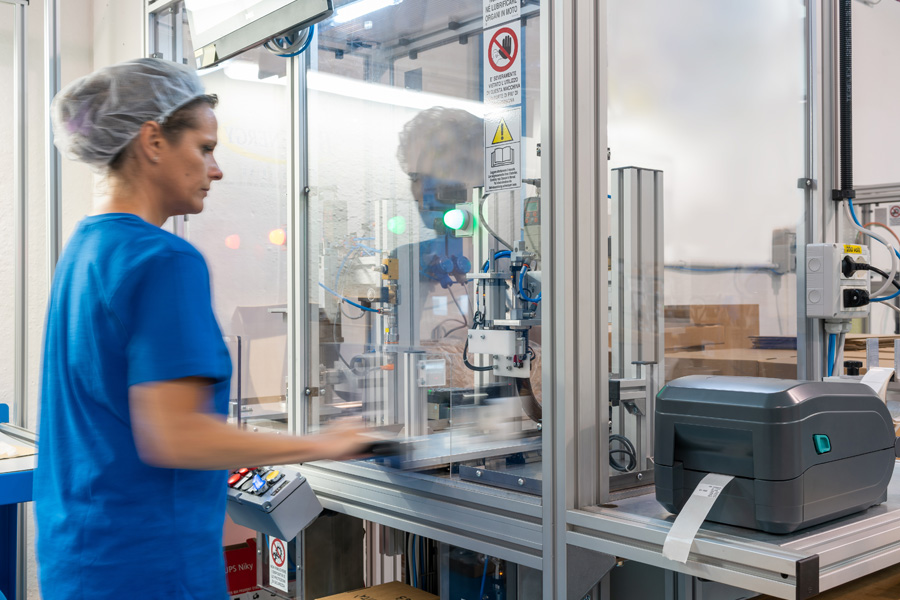

Can be manual, semiautomatic or completely automated, and we choose, share and use each type according to the different projects.

Traceability

Each single component on the worklist is tracked and recorded.

Monitoring

Continued, constant checks of the different machining processes.

Materials

Experience gained in managing various components in different materials: plastics, rubber, silicone, stainless steel, and leather, are just some of what we use.

Appliances

Eyewear

Housewares

Personalised Gift Items

Gadgets

Food industry

Contacts

Techno Assembly srl

Via dell’Artigianato 42

32016 Alpago (BL) – Italy

+39 0437 989082

info@technoassembly.it